-

Flexible Packaging Film

Premade Bags& Pouches

Premade Bags& Pouches Die-cut Lids

Die-cut Lids New Products

New Products

-

Snacks

Dairy

Dairy Beverage

Beverage Pet Care

Pet Care Confectionery

Confectionery Lawn& Garden

Lawn& Garden Processed Food

Processed Food Home&Personal Care

Home&Personal Care Meat, Poulty& Seafood

Meat, Poulty& Seafood Eco-solutions Family

Eco-solutions Family

-

Film Blowing

Die-cutting

Die-cutting Graphics& Printing

Graphics& Printing Pouch Converting

Pouch Converting Laminating& Coating

Laminating& Coating Innovation& Package Engineering

Innovation& Package Engineering Finishing& Slitting

Finishing& Slitting Quality Control

Quality Control

-

Company Environmental ResponsibilityFormalizing our ESG strategy for sustainable products by 2025 while prioritizing people and impact in our communities and the worldProactive Sustainability PackagingWe proactively engage and collaborate with employees, suppliers, and customers to minimize our facilities' environmental impact and energy usageOperation SustainabilityWe use advanced technology to develop sustainable, flexible packaging solutions and have developed sustainable product groups to increase our environmentally sound offeringsSocial SustainabilityWe prioritize social sustainability by promoting employee well-being and supporting local communities, and commit to sustainability extends to ethical and safe operations globally

Unleash Your Product's Potential with Our Cost-effective and Smart

Solutions - Discover Our Capabilities Today

Capabilities

关于我们

ABOUT US

Innovation& Package Engineering

While some flexible packaging manufacturers offer standard flexible packaging materials, at Copack we engineer customized flexible packaging structures designed specifically for your products.

We've specialized in flexible packaging for 15 years, and our expertise in polymer chemistry and flexible packaging engineering allows us to design optimal, cost-effective flexible packaging materials. We work with a vast range of films, foils, papers, and resins when engineering customized flexible packaging laminations.

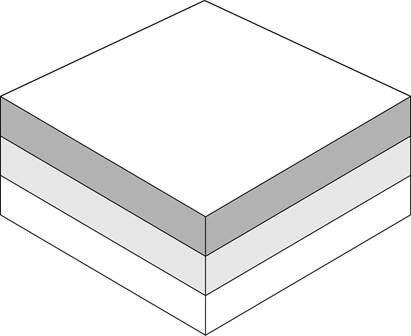

A flexible packaging structure typically consists of multiple layers of materials laminated together, with each layer performing a crucial role in your packaging’s performance and presentation.

Each layer provides specific performance characteristics, such as:

Oxygen, moisture, or light resistance

Chemical resistance

Puncture resistance

Tear resistance

Rigidity

Glossy or matte appearance

Opacity or translucency

Heat sealability

Print receptivity

The example below shows the duties each layer performs within a basic five-layer extrusion laminated flexible packaging structure:

1. Exterior Layer

· Provides dimensionally-stable print surface

· Protects the ink

· Protects the barrier layer

· Plays a role in burst strength & tear resistance

· Adds to overall pouch strength

2. Tie Layer

· Provides another layer of protection for the barrier layer

· Bonds the outside layer to the barrier layer

· Hides the color of the barrier layer

3. Barrier layer

· Provides chemical resistance

· Prevents moisture, light, and oxygen transmission

4. Tie Layer

· Bonds the barrier layer to the sealant layer film

· Provides protection for the barrier layer

5. Sealant Layer

· Allows the flexible packaging structure to be heat-sealable

· Provides burst strength

· Seals the product within

· Protects the barrier layer

Related Links: www.co-pack.net © Wenzhou Co-pack Co., Ltd. SEO Powered by www.300.cn